Chemists and process engineers of Otto-von-Guericke-University Magdeburg together with researchers at Universität Greifswald are using enzymes to hydrolyze bio-based PEF, which is a valuable alternative to fossil-based PET.

Impressions of the 3rd SmartProSys Symposium

29 September - 1 October 2025 | Festung Mark

The 3rd SmartProSys Symposium brought together over 120 participants including researchers, industry partners, and interdisciplinary experts at Festung Mark, Magdeburg to exchange ideas on sustainable chemical production and circular carbon strategies

📸 Browse photos and impressions --> here!

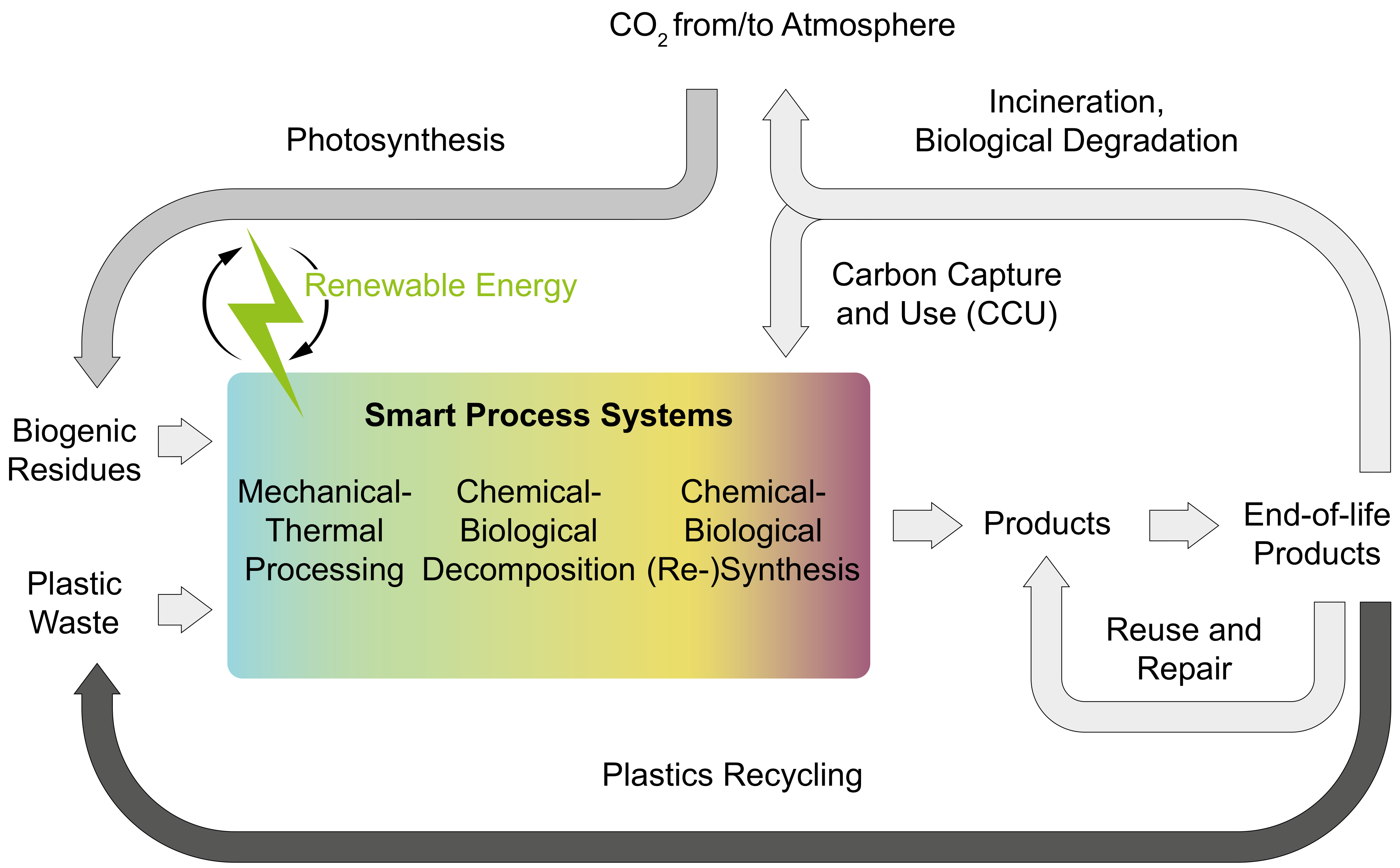

Smart Process Systems for a Green Carbon-based Chemical Production in a Sustainable Society

Welcome to the website of the Research Cluster SmartProSys! Here you can find current information about our research on smart & sustainable chemistry and circular economy.

The SmartProSys research initiative aims to replace fossil raw materials in chemical production with renewable carbon sources, thus contributing to a carbon-neutral society. It follows a system-oriented strategy and investigates resource-efficient degradation and synthesis strategies at process level, intelligent catalytic conversions at molecular level, and economic and societal impacts at a higher system level. The complexity of the system requires the development of powerful computational and machine learning methods for the design, simulation, optimization and control of the system. SmartProSys involves researchers from the fields of systems-oriented process engineering, chemistry, mathematics, logistics, political science, and psychology.

If you want to receive updates on SmartProSys, please subscribe to our newsletter.